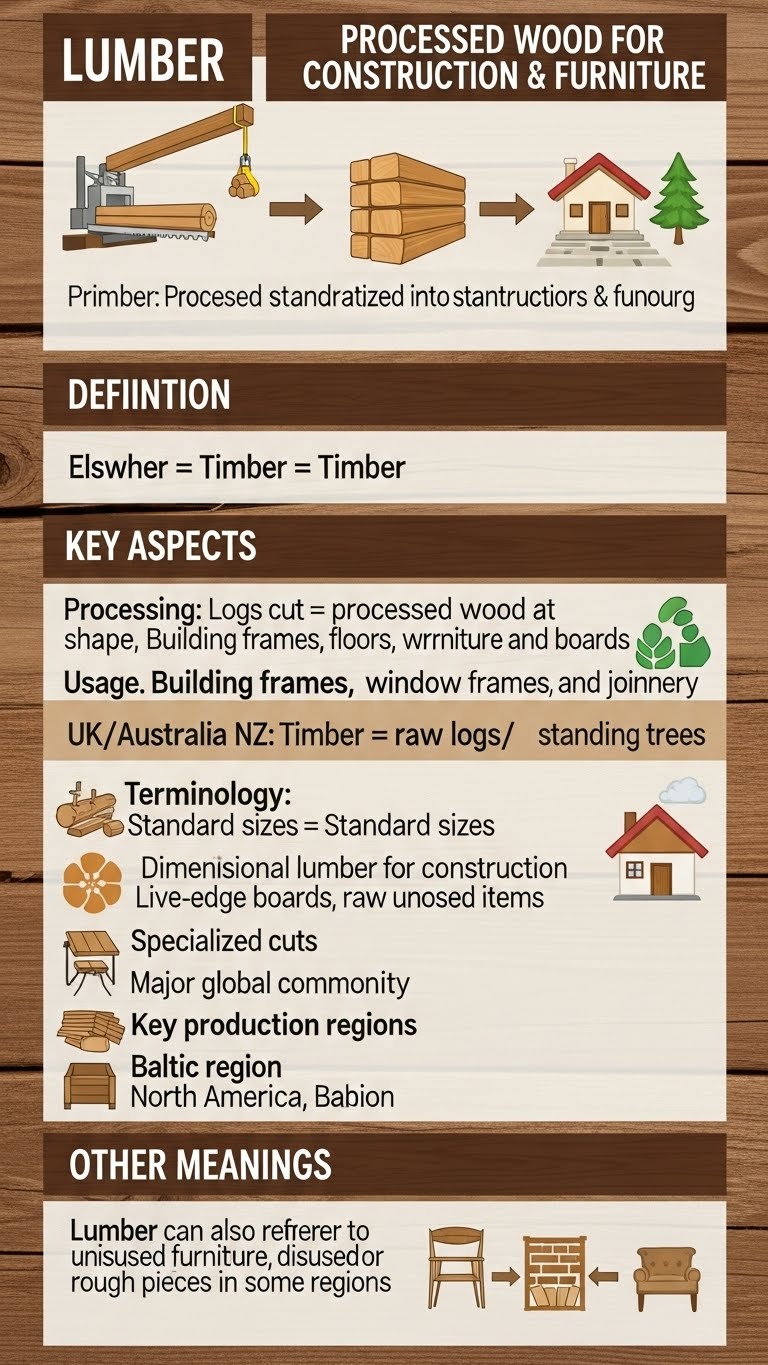

Freshly sawn wood shaped to standard sizes becomes what we call lumber. Mostly it goes toward making buildings, cabinets, chairs, that sort of thing. Across America and up through Canada people use “lumber” when talking about those tidy wooden pieces ready for building work. Raw tree trunks still unprocessed? Those are called timber there. Jump over to Britain or down under in Australia though, one word does it all – “timber” fits every stage.

What is Lumber? History and Terminology

Back then, “lumber” meant bulky things left sitting in storage. Over time, around the 1600s, folks started using the word for wooden planks made by sawing trees. These days, logs get chopped down first. After that, workers peel off the bark before slicing them up. The cutting method aims to reduce flaws – knots or curved sides, known as wane.

Softwood vs. Hardwood

Built from evergreens like spruce or pine. Fir also fits this group neatly. These come from forests where needles stay through winter

Available in sizes like 2 by 4 or 4 by 4

When it comes to building frames, this fits right in. Trusses often rely on its strength. Construction work uses it regularly. Its role stays steady across different jobs

Built tough, hardwood comes from leaf-shedding trees like oak. Think sturdy chairs or smooth trim – maple fits that role well. Cherry brings a warm hue to cabinets or detailed moldings. Each type shapes differently under tools, yet holds its form long after

Foot-by-board, that is how they sell it

Thickness uses a quarter-based count. Four quarters stack to one inch. Eight make two full inches

Turns out, a board called a 2×4 measures just 1.5 by 3.5 inches. The gap between name and size? It’s due to how wood gets processed after cutting

Drying pulls water out, making timber smaller. Shrinking happens when dampness escapes from lumber

Surface gets even as planing machines cut down size

A piece of lumber starts out bigger than what it becomes. Called nominal, that first cut measures two by four inches. Rough and ready, this is how it leaves the mill. Over time, planing smooths it down. What you get now differs from the starting point. Actual size shows up smaller after processing

A quarter inch less than the stated dimension defines the real width. Three and a half inches mark its actual span across. One and a half inches tall – that’s what it measures once set and dry. Final form comes in smaller than labeled

One hundred years ago, boards were built stronger; now they press together less tightly. That shift sliced their crushing resistance down close to a tenth.

What makes wood expensive? Home building picks up, costs jump. When loans cost more, fewer houses go up – less need for timber. Mills sometimes slow down, supply shrinks. Sudden shifts in any of these tilt the price one way or another. Markets react fast when builders buy heavy. A quiet construction season pulls prices lower. Trade rules tweak availability too. Weather halts logging now and then. Each piece fits into a larger puzzle

Housing demand climbs even as higher mortgage rates slow new construction. Fewer homes being built means less need for materials like lumber. Builders pull back when borrowing costs rise. This shift affects how much wood gets used across projects. Rising rates make financing tougher, so companies scale down plans. With fewer groundbreakings, timber orders shrink accordingly

Few mills running. When prices drop too low, factories often slow down work. This shrinking output can leave supply short

Shipping routes worldwide face hiccups now. Delays pile up when borders tighten rules. Movement slows across oceans and land crossings. Some goods get stuck without warning. Trade lanes shrink under new limits. Trucks wait longer at checkpoints. Ships circle ports with nowhere to dock. Supplies dwindle far from factories. Crossing borders takes more time than before. Delivery times stretch unpredictably

Lumber sits near five hundred fifty dollars for every thousand board feet lately – yet shifts fast without warning. Still, that number might not last till next month.

One thing about wood? It grows back, which helps keep things going round and round. Picture this: every cubic meter holds close to a full tonne of carbon dioxide. Still, tossing it away shows up as a big snag down the line

Most leftover wood ends up buried in trash sites. Around two out of every three parts never gets reused. Waste piles grow while usable material disappears underground. Landfills quietly collect what could have had another life

Burning waste to produce power accounts for 16 out of every 100 units. That method turns trash into heat used for electricity generation

17 percent is recycled

How to Improve Recycling Use reclaimed lumber for new projects

Convert wood waste into mulch or biomass fuel

Support products made from secondary raw materials

FAQ

Why isn’t a 2×4 actually 2 inches by 4 inches?

What you get starts as a measured log, still wet and untouched. Once it loses moisture and gets smoothed, its real shape shows – exactly one and a half by three and a half inches.

What is the difference between lumber and timber?

Freshly cut trunks? They’re called timber across Britain. But in North America, that name sticks only until processing begins. Once sawn into planks, they shift from timber to lumber there. Meanwhile, British usage keeps calling it timber – no matter the stage.

What level of dampness makes wood start to decay?

Mold shows up when levels rise past twenty-two percent. Wood stays safe if kept under nineteen. Moisture near twenty-five invites rot. Below that line, trouble slows down.

Wood can be a lasting resource – if handled with care. Making it pollutes less than producing steel or concrete while trapping carbon inside. Recycling still happens too rarely, yet forests renew themselves over time.

Halfway through a four-part split of hardwood – this setup splits logs into quarters – is what people mean by the quarter system.

Lumber thickness? It’s based on quarter-inch segments. Four quarters stack up to one full inch. When you see 8/4, that means two inches deep. Each step adds another half inch to the total.

What affects lumber prices today?

Fueled by homebuyer needs, lending costs shape how much mills produce. Though construction appetite shifts, factory response follows closely behind. When loans get heavier, building slows – factories adjust without delay.